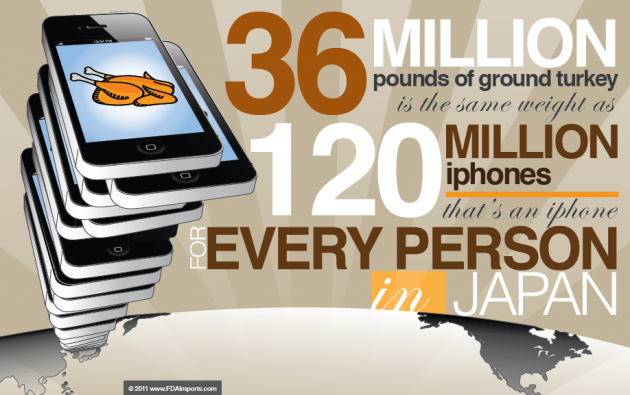

36 million pounds of ground turkey.

That’s a ton of meat, 18,000 tons of meat to be precise. That’s the weight of 120 million brand-new iphones (without the box). So if almost everyone in Japan bought an iphone-4 today and then put them all on a scale, that’s how much the recalled turkey meat would weigh.

Confused yet? Good.

An importer or manufacturer goes through this same kind of mental trauma every second of every day during a recall or food safety crisis. Cargill will spend a hefty sum this year on this unexpected food safety crisis but we can all learn a thing or two in the process. Every importer, exporter, manufacturer, and supplier should make sure they learn these three lessons from the “Epic Turkey Recall of 2011”. In no particular order:

1. Get Organized. Let’s face it; small and medium-sized companies often struggle to stay on top of their record keeping, both in habit and with technology. This is one major area that often gets lost in the everyday business shuffle. In the event of a food safety crisis however, nothing could be more important than fast, accurate, and precise batch, lot, and facility data. It could make the difference between a $10,000 recall and a $10,000,000 one. Get serious about your record keeping. Know what technologies you have in place and how they interface with your supply chain and process. An investment of time and software now could save you time and product later through being able to craft a specific, narrow recall.

2. Know Your Plan. You can bet that right now Cargill is diligently reviewing their production methods to analyze what went wrong and how they can prevent it in the future. Ideally, every food manufacturer should have a plan that identifies hazards and specifies preventative controls – in other words, a Hazard Analysis & Critical Control Points (HACCP) plan. Right now the law only requires seafood processors and juice manufacturers to have a HACCP plan.

Thanks to the Food Safety Modernization Act (FSMA) essentially every food facility must develop a Hazard Analysis and Risk-Based Preventive Controls (HARPC) plan (a HACCP plan by another name.) Effective July 4, 2012, every facility must develop a written plan, preventative controls, verification record keeping, re-evaluation protocols and self-conducting hazard analysis. That’s a lot of work so manufacturers should start getting their teams ready now.

And importers, you’re not of the hook either. You need to care about your suppliers’ HARPC requirements, because the FSMA requires you to verify that your foreign-suppliers comply with it. This verification process is not optional; noncompliance violates the law and an importer cannot import a food if the importer fails this requirement.

3. Think Like a GPS. Although not mandatory, Congress is pushing to establish regulations for tracking a single food from production to consumption. The FSMA requires FDA to run a pilot program that tests the methods for tracking food, after which FDA must report back to Congress about the feasibility and cost/benefits of such a tracking program. If FedEx and UPS can track a single package anywhere in the world, FDA is likely to conclude that such a program is feasible and that the benefits must outweigh the costs. By always knowing where your food is, you can efficiently target your resources to recall a food if it becomes necessary.

No amount of planning can account for everything and no one can oversee every inch of every facility at every second. Accidents happen and the unexpected will arise. Yet the difference between a little stress and an around-the-clock-nightmare comes when you’ve made preparations, done your homework, prepped your team, vetted your suppliers, and stayed on top of the regulations and rules. A company that makes these types of long-term investments is a company that will be around to see their efforts pay off.